Rheem furnaces are strong and efficient, but when ignition fails, airflow drops, or the system starts making unusual noises, you need an HVAC technician who knows the brand’s specific design.

We provide fast, same-day Rheem furnace repair for all models — from Classic Series to Prestige high-efficiency furnaces with variable-speed blowers and advanced control boards.

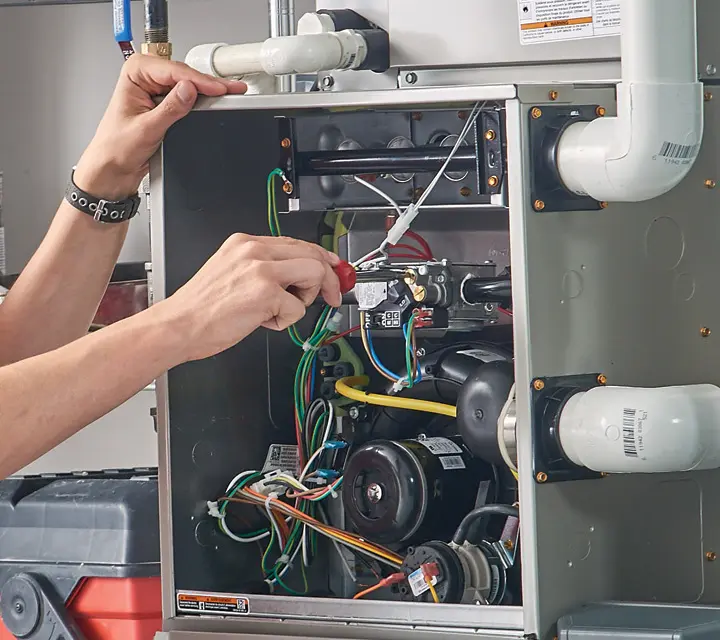

Our technicians accurately diagnose pressure switch failures, igniter problems, blower motor issues, and error codes common to Rheem heating systems — restoring reliable, safe heat in your home.

We proudly serve your service area with honest pricing, long-lasting repairs, and professional HVAC expertise.

1. HVAC Experts With Rheem System Experience

Rheem furnaces use unique control boards, limit switches, and draft inducers — our techs know how to diagnose them correctly.

2. Same-Day Furnace Repair

Most problems, including igniters, capacitors, motors, and pressure switches, are repaired in a single visit.

3. Upfront Pricing — No Surprises

You receive a clear, honest estimate before we start any work.

4. Repairs for All Rheem Furnace Models

Rheem Classic® Series

Rheem Classic Plus®

Rheem Prestige® high-efficiency models

Older Rheem natural gas furnaces

5. High-Efficiency & Variable-Speed Specialists

We repair condensation issues, ECM motor failures, airflow restrictions, and pressure switch faults found in high-AFUE Rheem systems.

6. Warranty on Parts & Labor

We guarantee quality repairs and long-lasting performance.

1. Rheem Furnace Not Heating

Often caused by igniter failure, burner issues, or an overheating limit switch.

2. Rheem Furnace Blowing Cold Air

May be due to airflow restriction, cracked igniter, or flame sensor malfunction.

3. Pressure Switch Stuck Open/Closed (VERY common on Rheem)

Rheem’s pressure switches are sensitive to drainage and venting blockages.

4. Rheem Blower Motor Not Running or Weak Airflow

Rheem units are known for blower capacitor failures and ECM motor problems.

5. Furnace Short Cycling (Turns On and Off)

Usually caused by overheating, poor airflow, or failed sensors.

6. Rheem Error Codes

We diagnose and repair codes such as:

Code 0 — Normal

Code 1 — Ignition failure

Code 2 — Pressure switch open

Code 3 — Pressure switch closed error

Code 4 — Limit switch open

Code 6 — Flame sense failure

Code 7 — Gas valve circuit issue

7. Noisy Operation (Rattling, Humming, Vibration)

Often linked to draft inducer wear, blower wheel imbalance, or loose components.

8. High-Efficiency Furnace Leaking Water

Rheem 90%+ AFUE furnaces frequently clog in the condensate trap or drain tube.

1. Quick Scheduling & Immediate Dispatch

You contact us — we assign the closest available HVAC technician.

2. Full Diagnostic of Your Rheem Furnace

We check:

Igniter

Burners

Flame sensor

Draft inducer

Pressure switches

Control board

Blower motor & capacitor

Drainage system

Thermostat communication

Airflow & temperature rise

3. Clear Explanation of the Problem

We show the failed component and explain your options in simple, honest terms.

4. Same-Day Repairs for Most Rheem Units

Igniters, sensors, switches, motors — repaired or replaced the same day.

5. Final Safety & Efficiency Testing

We verify ignition, airflow, CO safety, cycle timing, and efficiency performance.

6. Maintenance Tips for Rheem Furnaces

Filter care, drainage maintenance, airflow improvements, and thermostat guidance.

Rheem units commonly shut down from overheating, poor airflow, or pressure switch errors. We diagnose the specific cause.

This often indicates inducer motor wear, blower wheel imbalance, or loose furnace panels.

Cracked igniters, clogged burners, or ignition control issues are typical failure points.

Clogged condensate traps or drain lines cause leaks — we flush and repair the system.